20,000 Mattresses Recycled in CT's First-in-Nation Program Since May 1

/Connecticut’s first-in-the-nation mattress recycling program, Bye Bye Mattress, has recycled 20,000 mattresses since it began in May, according to program officials.

The groundbreaking program was established by state law in 2013, calling for the manufacturers and consumers of mattresses to pay for their end-of-life disposal under a concept called product stewardship. Connecticut has a similar product stewardship program for paint, one of only six states in the nation to institute that program.

The Connecticut mattress recycling program, launched on May 1, is funded by a $9 fee collected from consumers when a new mattress or box spring is sold. The program is administered by the Mattress Recycling Council, which is a 501(c)3 non-profit organization created by the International Sleep Products Association (ISPA). The organization’s Board of Directors includes individuals who are employed by some of the industry leaders, including King Koil, Serta Simmons, Tempur Sealy and Paramount Sleep. It is based in Alexandria, VA.

Under the program, dubbed “Bye Bye Mattress,” any used mattress that is discarded for municipal collection, picked up by a retailer, or dropped off by a consumer in Connecticut will be sent to a mattress recycler, who will break it down to reuse its components for other products.

Connecticut’s Public Act 13-42 (enacted in 2013 and amended in 2014) required the mattress industry to create a statewide recycling program for mattresses discarded in the state. When the program began, nearly 50 cities and towns across the state were participating to recycle the mattresses and box springs collected at their solid waste transfer stations.

Among those facilities is Park City Green in Bridgeport where employees break down old mattresses into its recyclable parts. Officials say they recycle 96 percent of mattress materials into usable products: the covers (which can be turned into mattress pads), the cotton stuffing (turned into fabric), the foam (automobile padding), wood pieces (mulch), and springs (reforged steel). The program diverts mattresses from waste-to-energy facilities and landfills and allows materials like fiber, foam, steel and wood to be reused.

Residents drop-off their used mattresses and box springs at no-cost. Then, MRC provides the collection container, transportation from the facility to the recycler and the mattress recycling services at no-cost. MRC continues to enroll interested municipal transfer stations in the program. A fact sheet about the program has been developed, Connecticut Recycling Program for interested municipalities, providing information about the benefits of participating.

A $2 reimbursement per mattress is only given at the program’s two participating recycling facilities (Recyc-Mattresses in East Hartford or Park City Green in Bridgeport). It is limited to four units per person per day; eight per person per year.

MRC is also working with mattress retailers, hotels, military facilities, universities, healthcare facilities and other public and private entities in Connecticut to divert mattresses from the solid waste stream. It will report the program’s progress to the state Department of Energy and Environmental Protection annually in October. Earlier this month, students and staff at Central Connecticut State University recycled mattresses from student dorms as part of the program.

A similar statewide mattress recycling program was adopted by the Rhode Island legislature in 2013 and is due to launch in 2016. To participate, Rhode Island producers must have joined the Mattress Recycling Council (MRC) by July 1, 2015, according to the organization’s website. Producer is defined as any person who manufactures or renovates a mattress that is sold, offered for sale or distributed in Rhode Island under the manufacturer’s own name or brand. California’s program, enacted in 2013 and amended in 2014, is also expected to begin statewide in 2016, administered by the Mattress Recycling Council.

A similar statewide mattress recycling program was adopted by the Rhode Island legislature in 2013 and is due to launch in 2016. To participate, Rhode Island producers must have joined the Mattress Recycling Council (MRC) by July 1, 2015, according to the organization’s website. Producer is defined as any person who manufactures or renovates a mattress that is sold, offered for sale or distributed in Rhode Island under the manufacturer’s own name or brand. California’s program, enacted in 2013 and amended in 2014, is also expected to begin statewide in 2016, administered by the Mattress Recycling Council.

The MRC notes that more than 50,000 mattresses end up in landfills every day. The recycling programs aim to reduce that number. Each year, 35 to 40 million new mattresses and box springs are sold in the United States, and at least 15 to 20 million used mattresses and box springs are discarded.

https://youtu.be/Gsi6KgnvJF4

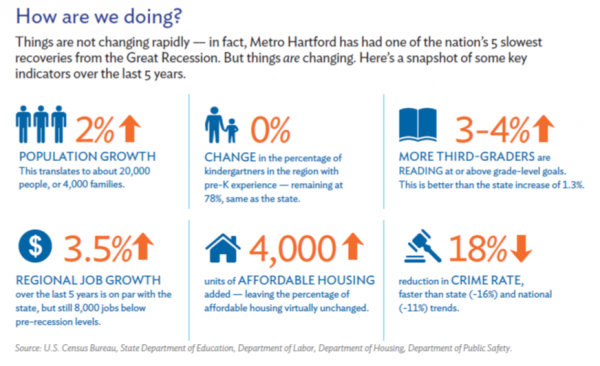

Looking at five year trends, the report found that the region’s population of about 1 million people has grown by 2 percent, which translates to about 20,000 people or about 4,000 families. Regional job growth, 3.5 percent, is on par with the state, but remains about 8,000 jobs below pre-recession levels. The crime rate across the Greater Hartford region has been reduced by about 18 percent during the past five years, faster than the state (-16%) and national (11%) trends.

Looking at five year trends, the report found that the region’s population of about 1 million people has grown by 2 percent, which translates to about 20,000 people or about 4,000 families. Regional job growth, 3.5 percent, is on par with the state, but remains about 8,000 jobs below pre-recession levels. The crime rate across the Greater Hartford region has been reduced by about 18 percent during the past five years, faster than the state (-16%) and national (11%) trends.

Partner organizations in developing the report include the Hartford Foundation for Public Giving, Capital Workforce Partners, Capital region Council of Governments, Metro Hartford Alliance, Hispanic Health Council, United Way of Central and Northern Connecticut, Urban League of Greater Hartford, Center for Urban and Global Studies at Trinity College, and the City of Hartford.

Partner organizations in developing the report include the Hartford Foundation for Public Giving, Capital Workforce Partners, Capital region Council of Governments, Metro Hartford Alliance, Hispanic Health Council, United Way of Central and Northern Connecticut, Urban League of Greater Hartford, Center for Urban and Global Studies at Trinity College, and the City of Hartford.

The survey noted that more than two-thirds of consumers (68 percent) looking to purchase their first home are interested in move-in ready homes while one-third would like to buy a fixer-upper. And when it comes to amenities, respondents are most interested in their first home having a backyard or pool and an attractive design, followed by energy efficient / smart homes technologies.

The survey noted that more than two-thirds of consumers (68 percent) looking to purchase their first home are interested in move-in ready homes while one-third would like to buy a fixer-upper. And when it comes to amenities, respondents are most interested in their first home having a backyard or pool and an attractive design, followed by energy efficient / smart homes technologies.

U.S. Commerce Secretary Penny Pritzker honored a total of 45 American companies and organizations, many of which are small- and medium-sized enterprises (SMEs), at the 2015 President’s “E” Awards ceremony, held earlier this year. The six Connecticut businesses were among the 45 honored.

U.S. Commerce Secretary Penny Pritzker honored a total of 45 American companies and organizations, many of which are small- and medium-sized enterprises (SMEs), at the 2015 President’s “E” Awards ceremony, held earlier this year. The six Connecticut businesses were among the 45 honored.

Proton Onsite makes hydrogen and nitrogen generators. Mutualink manufactures equipment used to facilitate collaborative communication between public safety and first response teams at the scene of emergencies. Jonal Laboratories makes sealant used in the aerospace industry. Dymotek manufactures custom injection molded plastic and silicone parts for electronics, plumbing valves and juice dispensers.

Proton Onsite makes hydrogen and nitrogen generators. Mutualink manufactures equipment used to facilitate collaborative communication between public safety and first response teams at the scene of emergencies. Jonal Laboratories makes sealant used in the aerospace industry. Dymotek manufactures custom injection molded plastic and silicone parts for electronics, plumbing valves and juice dispensers.

t assist and facilitate export activities were honored with the “E” Award for Export Service. Four firms received the “E” Star Award for Exports, which recognizes previous “E” Award winners who have reported four years of additional export growth. And, three companies were awarded the “E” Star Award for Export Service, which recognizes previous “E” Award winners that have shown four years of continued support of exporters since first winning the “E” Award.

t assist and facilitate export activities were honored with the “E” Award for Export Service. Four firms received the “E” Star Award for Exports, which recognizes previous “E” Award winners who have reported four years of additional export growth. And, three companies were awarded the “E” Star Award for Export Service, which recognizes previous “E” Award winners that have shown four years of continued support of exporters since first winning the “E” Award.

This year marks the 53rd anniversary of the

This year marks the 53rd anniversary of the