4 Renowned CT Manufacturers to be Inducted into Hall of Fame; Timex, Cheney Brothers, Farrel, Handy & Harman to be Honored

/Timex Group USA (Middlebury), Cheney Brothers (Manchester), Farrel Corporation (Ansonia), and Handy & Harman (Fairfield) will be inducted into the American Manufacturing Hall of Fame in Connecticut this fall, in the fifth annual ceremony.

The American Manufacturing Hall of Fame (AMHoF) celebrates the innovative history of American manufacturing, raises funds for educational programs and promotes awareness of advanced manufacturing, which is critical to the economy.

The Hall of Fame is affiliated with the Housatonic Community College (HCC) Foundation in Bridgeport, which also serves as fiduciary. BlumShapiro will serve as the Founding Platinum Sponsor of the ceremony for the fifth consecutive year. The 2018 AMHoF Induction Ceremony will take place on October 9 at the Trumbull Marriott.

The AMHoF has also announced that Robert Klancko is the recipient of its 2018 Leadership Award. Klancko has been a manufacturing leader in Connecticut’s manufacturing community for several decades. He has been a partner in his consulting firm of Klancko & Klancko LLC, and held key managerial positions for 20 years in the brass industry and another 15 years in the utility industry.

Timex began as the Waterbury Clock Company in 1854, and initially gained success with its dollar pocket watches. Renamed Timex in 1941, the renowned world-wide brand has its headquarters in Middlebury. Cheney Brothers was a center of the silk industry in the late 19th and early 20th century in Manchester. The 175-acre historic district in Manchester, includes over 275 mill buildings, workers houses, churches, schools and Cheney family mansions.

Timex began as the Waterbury Clock Company in 1854, and initially gained success with its dollar pocket watches. Renamed Timex in 1941, the renowned world-wide brand has its headquarters in Middlebury. Cheney Brothers was a center of the silk industry in the late 19th and early 20th century in Manchester. The 175-acre historic district in Manchester, includes over 275 mill buildings, workers houses, churches, schools and Cheney family mansions.

Founded in 1848, Farrel Corporation is based in Ansonia. During the American Civil War, they produced bayonets and cannon barrel. Today, they manufacture process equipment for the plastics industry, and employ roughly 100 people. Handy & Harman leveraged an early market advantage in silver bullion through acquisitions to provide not only bullion but alloys and prefabricated silver bands, wires, and moldings, as well as reclamation services to leading jewelers.

Klancko has contributed tirelessly to the field of technical education since 1972. He served as an educator at both the former Hartford Graduate Center and Waterbury State Technical College, and more recently at Mattatuck Community College. More recently, Klancko worked to educate educators in the Materials Manufacturing Summer Teachers' Institute at Southern Connecticut State University. He has also chaired and co-founded Environmental Studies and Materials Technology Advisory Committees at a number of state public and private colleges.

2017 inductees into the American Manufacturing Hall of Fame were Better Packages, MacDermid Performance Solutions, R.C Bigelow, Stanley Black & Decker and Ulbrich Stainless Steels & Specialty Metals. In 2016, the inductees were Bead Industries, The Benedict & Burnham Mfg. Co.; C. Cowles & Co., Chance Vought & Platt Brothers & Co.

The manufacturing firms added to the Hall in 2015 were Bridgeport Brass, Moore Tool, Inc. and Wheeler & Wilson/Singer, from Bridgeport, and A.C. Gilbert, Brewster Carriage and Auto and Sargent Co., from New Haven. In the inaugural year of the Hall of Fame, the inductees were Bridgeport Machines, Bullard Machine Tool, Hubbell, Inc., Sikorsky Aircraft Corporation and Warner’s.

The American Manufacturing Hall of Fame is comprised of “a group of passionate citizens and manufacturers who believe it is important to appreciate and understand the proud history of American Manufacturing as a catalyst to take advantage of the distinct opportunities that advanced manufacturing can bring to American lives today and in the future.” It was launched in Bridgeport at HCC, because the city was a “hub of manufacturing leadership and innovation in America for over a century, the organization’s website points out.

The site highlights that the first practical submarine, the first practical carbon electric light bulb filament, the modern automobile assembly line and the first robot all have their roots in, or were invented, in Bridgeport.

Any company engaged in manufacturing for at least ten years can be considered for induction. Companies considered have made “significant contributions to the field of manufacturing either by innovation, the improvement of a manufacturing process or by creating a product that has advanced humankind.”

Founding sponsor BlumShapiro is the largest regional accounting, tax and business advisory firm based in New England. The HCC Foundation was founded in 1990 to provide financial assistance to the College and its students beyond the fundamentals provided by the State of Connecticut. Tickets to the induction ceremony event are now available.

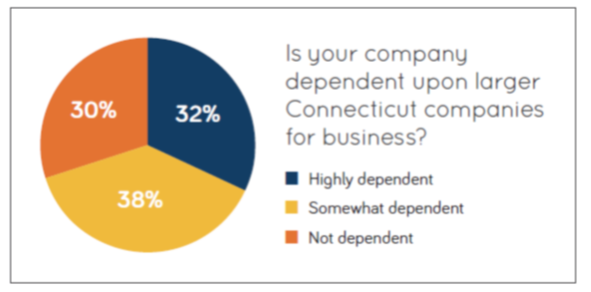

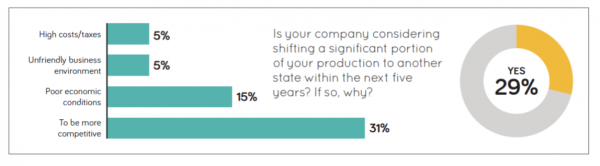

Whether perception drives reality or reality is drives perception, the opinions stated by business surveyed are less than encouraging, according to the report. Primary reasons cited for moving or expanding outside Connecticut are the state’s high costs (including taxes) and its “anti-competitive business environment,” reflecting an oft-stated CBIA viewpoint. More than three-quarters say Connecticut’s business climate is subpar compared with other states in the Northeast, and the nation.

Whether perception drives reality or reality is drives perception, the opinions stated by business surveyed are less than encouraging, according to the report. Primary reasons cited for moving or expanding outside Connecticut are the state’s high costs (including taxes) and its “anti-competitive business environment,” reflecting an oft-stated CBIA viewpoint. More than three-quarters say Connecticut’s business climate is subpar compared with other states in the Northeast, and the nation.